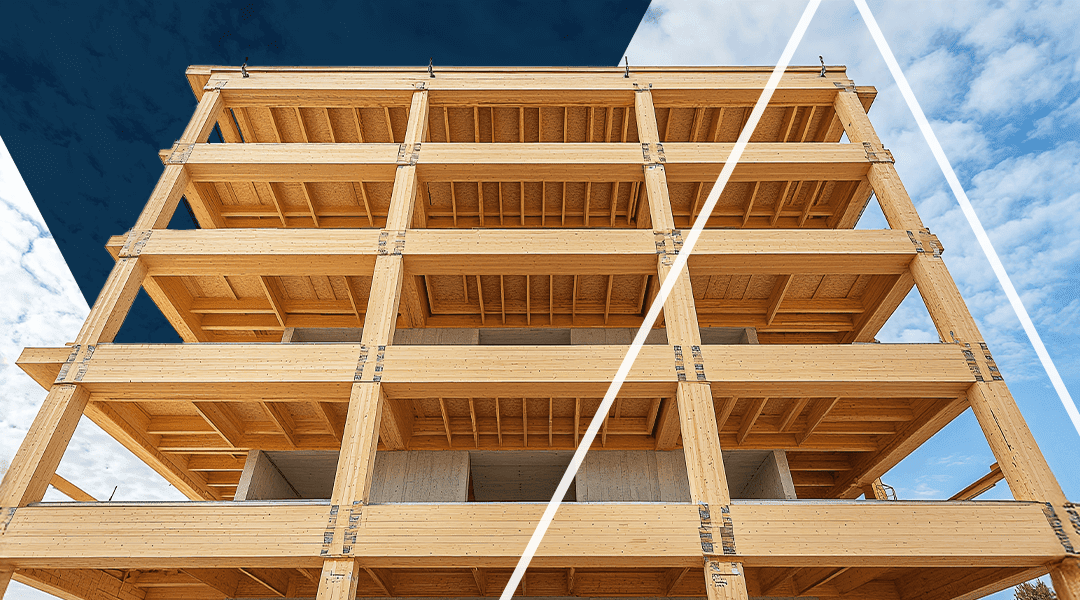

Wood has been used for construction throughout human history. However, it was slowly phased out of the construction industry over the last two centuries as steel and concrete became more popular. Today, research and technological advancements have brought timber back into the spotlight as a strong, safe and sustainable alternative. One of the building techniques spearheading timber resurgence is mass timber construction, which relies on massive timber panels and beams to create a building’s primary load-bearing structure.

What Is Mass Timber?

Mass timber, which means massive timber, is a construction material created by joining pieces of wood to form large wooden products, such as wall and floor panels, beams and columns. The technique creates large, structurally sound materials that match the strength of concrete and steel while being lighter and environmentally friendly.

The concept of sticking wood together to create incredibly strong building materials gained traction in Europe throughout the 1980s and 1990s and became more popular in the early 2000s. The adoption of mass timber for bigger buildings by North American architects during the 2010s fueled the style’s incorporation into the International Building Code (IBC) in 2015. In Canada, the adoption of mass timber has become widespread. Meanwhile, the style continues to receive strong support from U.S. states like Oregon and Washington.

Wood for mass timber projects has sustainable origins and is sourced mainly from responsibly managed forests in North America. These sources are usually young trees with low environmental impact and small trees that are less commercially desirable.

Types of Mass Timber

There are several methods of layering wooden pieces to produce mass timber and that’s what creates the various types. Here are the most common types of mass timber:

- Cross-laminated timber (CLT): The most popular mass timber type is CLT, which is made by gluing lumber boards crosswise. Long pieces of lumber are laid side by side to create panels, with each panel positioned to follow a perpendicular direction against the previous layer. The design forms robust load-bearing panels with similar strength to concrete and steel.

- Glue-laminated timber (GLT): Unlike the crisscrossed CLT design, GLT is made by positioning lumber pieces parallel to one another to form beams and panels. However, both styles utilize structural adhesives for gluing.

- Nail-laminated timber (NLT): NLT focuses on the method of securing individual lumbers rather than the layering style. It’s a type of mass timber that utilizes nails or screws to secure structural panels instead of adhesives.

- Dowel-laminated timber (DLT): Instead of nails and glue, DLT uses hardwood dowels to secure layers of lumber. This creates dimensional stability and adds to DLT’s architectural flexibility. Since the style doesn’t rely on nails or adhesives, it’s the strongest option for projects requiring all-wood composition.

- Laminated strand lumber (LSL): LSL is created by bonding parallel wood strands to form large blocks that are later cut into smaller LSL products. The process involves clipping or shredding wood veneers into long strands or flakes, applying adhesives and pressing them into blocks. The style offers strength, stiffness and dimensional stability.

- Mass plywood panel (MPP): MPP is one of the new ways of making mass timber products. It involves gluing and pressing dense wood veneers to produce large panels, beams and columns. The process creates stronger and denser products than alternatives that use lumber as the main raw material.

Advantages of Mass Timber Construction

Mass timber combines traditional wood building with today’s technology to create strong building products with competitive advantages over other construction materials. Here are some of the benefits of mass timber construction:

1. Fire Resistance

Since tall buildings need to be structurally sound enough to resist fire, steel and concrete have long been the go-to materials. Contrary to popular belief, wood is just as or even more fire-resistant than steel under specific conditions. While lumber in stick frame constructions has a poor fire rating, mass timber is proven to have incredibly high fire and blast resistance rates.

The massive wood panels and blocks have natural fire-resisting capabilities. For example, since the outer layer chars during a fire, it discourages further burning through insulation, which retains the building’s structural integrity. Also, unlike steel, heavy wood doesn’t react to excess heat, becoming compromised.

2. Faster Construction

Mass timber construction uses factory-assembled products similar to prefab concrete, eliminating the need for labor-intensive on-site material preparation. Since materials arrive ready for installation, there won’t be many of the initial steps associated with traditional construction, making the building work faster and more efficient.

3. Reduced Costs

Considering mass timber products are designed and cut to specifications at the factory, it offers the opportunity to reduce labor costs because you won’t have as many workers as the typical concrete construction. In addition, using precise prefab products eliminates the expenses associated with material waste.

4. Load-Bearing Strength

Unlike other building materials, mass timber is not vulnerable to bending and cracking due to severe stress. Multiple layers of load-bearing panels offer exceptional strength and stability without making the material too heavy. The remarkable performance of mass timber in tests that measure structure integrity is a testament to its robust nature and low-weight characteristics.

5. Sustainable

Every year, non-wood building and infrastructure materials account for 15% of global CO2 emissions. Responsible sourcing and manufacturing of mass timber products offers a more eco-friendly alternative and a lower carbon footprint. Mass timber also offers the opportunity to thin forests with unfavorable trees, creating more room for healthy tree growth.

Use of Timber Frame Brackets

While heavy wooden products make up the primary load-bearing structure of mass timber buildings, wood is not the only element — steel fabrications play a big role in enhancing connections and adding accents for aesthetic value. Both timber frame construction, which involves heavy timber, and mass timber construction can benefit from various types of timber frame brackets. Advantages of timber frame brackets include:

- Enhanced durability: Steel has excellent qualities, including high strength, which helps reinforce connections, especially in sections that span long distances. Also, the resistance to corrosion and decay allows the accents to withstand the elements.

- Improved stability: Steel connections add strength to help eliminate challenges like joint movements, providing additional stability.

- Design flexibility: While steel is ductile, wood is not. Incorporating steel creates more room for design flexibility, allowing architects and engineers to work with more angles, resolve misalignments and meet load requirements in mass timber.

Timber frame brackets vary from joist and beam hangers to corner and facial brackets. Since reliable providers offer custom-made solutions, you can invest in connections that match design requirements.

Discover Our Timber Frame Brackets

Discover Timber Frame Brackets at Mid-Atlantic Steel Fabrication

Mass timber construction calls for superior steel connections and finishing for the ultimate look and stability. Complement your innovative project with reliable metal fabrication services and steel reinforcement from Mid-Atlantic Steel Fabrication. Our in-house industry-certified team will work with you to provide brackets that fit your design and aesthetic demands. Explore our website to learn about timber frame brackets and other solutions we offer!