POWDER COATING

If you’re looking for improved durability and aesthetic appeal for metal works, our industrial powder coating service in Lancaster, PA exceeds the limitations of traditional painting methods. This dry finishing process protects metals from corrosive elements while improving their overall appearance.

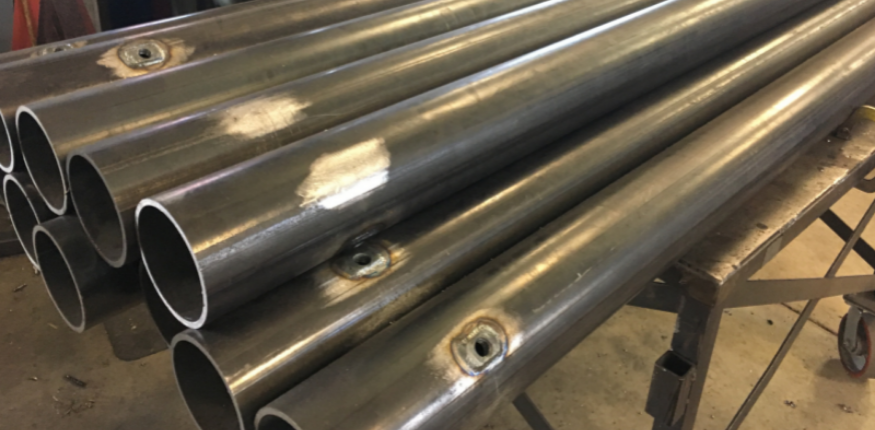

Create a protective and decorative barrier on metal parts with our powder coating services.

Our Powder Coating Services Near Lancaster PA

Our metal fabrication services include powder coating, during which professionals finish projects of any size with a high-quality coating. While custom powder coating is an outsourced service, we ensure that the finished products are at par with our stringent standards for protection and visual appeal.

Custom Powder Coating Capabilities

At Mid-Atlantic Steel Fabrication, we are committed to making your life easier by providing a complete set of metal fabrication services. Metal powder coating is a value-added service to ensure high-quality metalwork with increased longevity and improved appearance. Beyond that, our dedication to superior work and extensive experience allow us to tailor our services to every client’s needs and project requirements.

The Industrial Powder Coating Process

Powder coating undergoes an electrostatic process using dry powder and an electrical charge for a final finish. The dry powder can be made from various materials, such as polymer resins, relevant curatives and key leveling agents. This powder then comes in different colors and unique textures.

When applying powder coating, these three processes are key to excellent results:

- Cleaning and preparation: Prepare the surface by cleaning, washing, rinsing and drying the product. This crucial step removes contaminants that may impact the coating process and workpiece quality.

- Powder application: After making sure that the surface is clean and free from contaminants, it’s time for coating, either using an electrostatic spray deposition (ESD) or a fluidized bed. While the manner of application varies on the method used, the main objective is the same — to distribute the powder evenly and smoothly over the surface.

- Product curing: The final step is to cure the surface to melt the powder and fuse with the metal. The curing duration varies, depending on the type of coating used and the application method followed.

Industrial Applications of Powder-Coated Metalworks

Powder coating is widely used in various sectors as the last step of metalwork finishing. Some industries that benefit from this dry-finishing process include:

- Architecture

- Construction

- Electrical

- Industrial

- Residential

Get Started By Requesting a Quote

Powder coating is a pivotal procedure that helps in the overall durability and appearance of the metalwork. With MA Steel Fab, we deliver a premium coating finish that meets your overall requirements. Count on us for this value-added service, along with exceptional metal work services, from designing to cutting and metal forming. We are your one-stop shop for all your metal fabrication needs. Get a free quote on your project today by completing the form below or get in touch with our team at (717) 687-2995 to learn more.