Precision can make or break a project when it comes to metal fabrication. This is why laser cutting has become the go-to solution for industries where accuracy is a priority. Whether designing intricate components or producing parts that must meet high precision qualities, you need tools that deliver clean and exact cuts on metal, and that’s where laser cutting comes in.

But how precise can a laser cutter cut, and what makes lasers stand out? This guide explores laser cutting capabilities and explains why it has become essential in industries that demand precision and flawlessness.

What Is Laser Cutting?

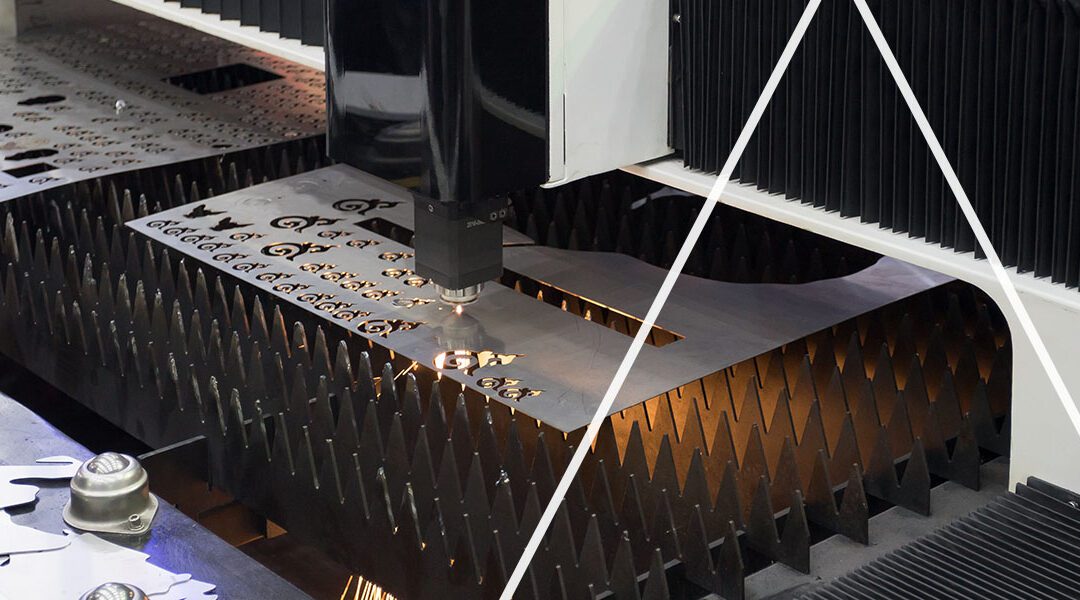

The technology behind industrial laser cutting utilizes an intense, focused beam of light or stream of photons to cut through materials, most commonly metals such as steel and aluminum. The laser is guided by Computer Numerical Control (CNC) systems, which ensures precision even for complex designs.

Once you input your design into the computer, the laser is directed to trace it exactly, producing the desired shape and pattern with minimal waste and a smooth finish.

So, how accurate is laser cutting? These machines can achieve tolerances that compare to the width of a human hair. This precision varies depending on the material thickness and the capabilities of the specific laser-cutting machine.

But how are metal laser cutters precise? Besides the computer-guided technology, other factors that contribute to the incredibly high laser cutting accuracy include:

- Coherent photons: Laser cutting uses a consistent stream of photons focused into a steady, powerful beam, ensuring precise cuts.

- Fiber optics precision: Modern laser cutters use fiber optic lenses to guide the laser beam precisely. This improves control, making the laser’s point of focus clearer and more direct.

- Minimal material damage: Unlike other cutting methods, laser cutting avoids direct contact with the material. The heat from the laser performs the cutting, minimizing damage to the surrounding material and ensuring more consistent results.

These capabilities allow for high levels of intricacy and consistency, making it perfect for detailed work.

Who Uses Laser Cutting?

Laser cutting is widely used across industries where accuracy and efficiency are nonnegotiable. This technology’s versatility and precision support everything from one-off designs to large-scale industrial production. The technology is also useful beyond aluminum and steel, providing precision cuts for wood, glass, and plastic materials.

Here are a few of the key sectors that rely on the accuracy of laser cutting:

- Architects and designers: Laser cutting is crucial in creating custom architectural metalwork for indoor or outdoor applications. Its precision delivers reliable designs and aesthetics while maintaining structural integrity. Some of these metalwork projects that would benefit from laser cutting accuracy include gates, fences, decorative metal screens, exterior and interior railings, staircases, pavilions, and safety railings.

- Medical device makers: In medical manufacturing, there’s no room for error — precision, consistency, and safety are essential. Laser cutting’s high accuracy is particularly beneficial in the fabrication of surgical instruments, enclosures for sensitive and delicate medical devices, and hospital furniture.

- Construction firms: The construction industry depends on durable, precisely fabricated metal components like beams, brackets, girders, screws, nuts, and bolts. Laser cutting ensures that each piece meets exact structural requirements for optimal performance.

- Agricultural industry: Laser cutting is used to manufacture components for equipment such as tractors, spreaders, chassis, and grain-handling machines.

Why Use Laser Cutting

Laser cutters offer many advantages over traditional metal cutting technologies, such as waterjet cutting and electrical discharge machining (EDM). Whether you’re building prototypes, large-scale structures, or custom components, laser cutting is your go-to solution. Here’s why:

- Unmatched precision and accuracy: Laser cutting is incredibly accurate. With the CNC-guided technology, you can achieve repeatable results every time, even on the most complex designs.

- Cleaner cuts requiring minimal finishing: Unlike traditional cutting methods, laser cutting produces smooth edges that rarely require additional finishing work. You’ll save time on grinding, polishing, or deburring. This speeds up the production process and reduces labor costs.

- Speed and efficiency: Laser cutters are fast in setup and execution. Once you upload your design, the machine handles the rest, automating the process via integrated software. Speed and precision are rare combinations in machine fabrication. However, laser cutting automation provides both, making them effective for large-scale productions.

- Works well with complex designs: Laser cutting can handle intricate and complex shapes with ease. The focused beam allows for highly detailed cuts, even on materials that are difficult to work with. This precision minimizes the need for additional post-processing.

When to Use Laser Cutting

Laser cutting is a wise choice when your project demands exact cuts, metal etching, and clean results that don’t leave marks or irregularities on the material. But when exactly should you use it over other methods like precision metal cutting, which use state-of-the-art machines?

The following are common scenarios when laser cutting is ideal:

- Tolerances are tight: Laser cutting is the answer if your project requires intricate shapes or strict dimensional accuracy. Thanks to CNC control and powerful optics, laser cutting delivers consistent results, even on designs with low tolerances.

- High-quality finishes: Use laser cutting when edge quality is important to your project. Unlike mechanical cutting, laser cutting melts instead of tearing through the material. The result is usually clean edges and smooth surfaces that reduce or eliminate the need for additional processing.

- Working with thin sheet metal: Laser cutting excels on materials like steel or aluminum in thinner gauges.

- Limited time: Laser cutting is typically an automated process, which significantly reduces the time required to produce precise and repeatable cuts. If you need speedy production, laser cutting is the solution.

How to Use Laser Cutting Machines

Operating a laser cutter requires professional skills to ensure high-quality work and minimize the potential for errors.

A laser cutter expert handles key tasks before cutting, such as selecting lenses, initiating programs, and calculating machine specs and parameters based on the provided material.

The cutting process then begins with:

- Design upload: The digital design is the roadmap that the machine follows and reads as precise cutting paths.

- Material preparation: With the material ready, you place it onto the cutting bed. The laser cutter will then auto-adjust to the material’s thickness and composition to ensure peak laser cutting accuracy.

- Cutting: With the design loaded and material secured, the laser cutter uses a high-powered beam, guided by CNC controls, to melt and cut the required pattern into the material.

Laser Cutting Services at Mid-Atlantic Steel Fabrication

Laser cutting is one of the most advanced cutting technologies today, delivering incredible accuracy down to fractions of a millimeter. Whether crafting intricate architectural metalwork, medical components, or heavy-duty construction parts, this technology offers consistency, speed, and reliable results.

At Mid-Atlantic Steel Fabrication, we bring your designs to life with accurate cuts and expert craftsmanship — every single time. If you’re ready to get started, request a quote or call us at 717-687-7313 to discuss how we can help with your next project.