At Mid-Atlantic Steel Fabrication, we offer welding services using quality equipment and experienced welders who pride themselves on attention to detail. Our welders are certified and trained to meet the specifications of both our industry and our customers.

Understanding the Different Types of Welds and Welding

At Mid-Atlantic Steel Fabrication, we offer the most common types of welding services. There are several welding processes, but the most commonly used include TIG (tungsten inert gas) and MIG (metal inert gas). The TIG welding process is versatile in terms of the variety of metals that can be used, but the process is slower. MIG welding is a faster process, but it is best suited for large and thick materials. The welds are not as precise in this process.

How to Tell a Good Weld from a Bad One

All welds are not created equal. A bad weld is not only unsightly, but it can also be unsafe. Take a look at the weld: Are there visible cracks? Are there splatters around the joinery? Does the seam appear messy? Is the welding line thin? Different welding methods yield different results and carry their own degrees of difficulty in achieving a good weld. If there is a seamless fit in the joint, or you don’t see evidence of a weld at all, then you are looking at a very good weld.

Characteristics of a Good Weld

The sign of a quality and secure weld is that you will not see the weld at all. If there is any visible evidence of a weld, it will be in the form of a bead that has no holes or cracks and is uniform overall. A high-quality weld is made using high-quality materials. In addition to a nice appearance, a high-quality weld has the strength required to keep multiple pieces of material fused together and to perform their intended job as an entire structure. The weld at the joint will be the same strength as the material that is joined.

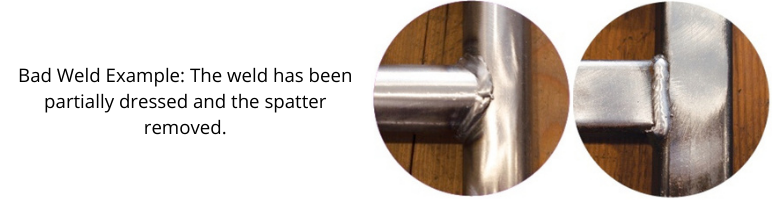

Characteristics of a Bad Weld

When you inspect a bad weld, on the other hand, it will have a messy appearance. It may even look and feel unstable. The joint at a bad weld will not be strong and secure. There are several dangers associated with a bad weld. A poor-quality weld can lead to faults or breakage in the fabricated structure. A bad weld can also create uneven joints or have jagged edges that can catch on and destroy materials and equipment. It can also harm people and animals.

What Questions Should You Ask Your Welder?

A certified metal welding professional works with a high-level attention to detail. He or she will have a high degree of training and experience. Some may even have specialized training and certification to perform specialized welding activities.

Superior workmanship is important! Your welder should understand how best to achieve your goals. To find the best person for your welding needs, ask them the following questions:

- What specialized training and certifications do you have? Minimal training for a certified welder is 6–8 months. A professional welder will have certification through the AWS (American Welding Society).

- How many years have you been welding? Experience is important!

- What is your specialty? Different welding processes are for different welding outcomes. Be sure the person you choose knows what they are doing with your metal.

- How do you keep up with training and certification? Technology changes constantly. A welding professional should always be learning and keeping up with appropriate certifications.

- Where are your metal and other materials sourced? You may hire the best welder in their class, but your weld will only be as good as the materials they use. Inferior materials lead to inferior results.

Being aware of basic welding techniques and the different types of welds ahead of time is what makes the difference between your project having a good weld or a bad weld. Mid-Atlantic Steel Fabrication’s certified welders use only the highest-quality materials and can handle a range of material thicknesses — from thin-gauge sheet metal all the way to heavier structural plates — and our capabilities can accommodate single-part projects or higher-volume production runs. For quality craftsmanship down to the smallest detail, contact us today!