Timber frame joinery is an intricate technique that securely connects a wooden frame without using nails or screws. Instead, it relies on carefully crafted interlocking joints that connect beams and posts. This age-old woodworking craft creates beautiful buildings.

From simple mortise-and-tenon joints to intricate dovetail joints, each timber frame joint type is crucial for the structural integrity and architectural elegance of buildings and furniture pieces. Understanding each type’s application, strength and how steel connections can increase your project’s longevity will ensure construction success.

Carpentry vs. Joinery

Wood is an incredibly versatile material crafting and construction — it requires a balance of craftsmanship and mastery. Carpentry deals with the overall construction of timber frames, playing a distinct role in building structural elements, simpler joints and other aspects that emphasize functionality and practicality.

In contrast, joinery focuses on the finer details and connections that hold the frame together. It creates detailed, intricate connections and complex joints, highlighting the aesthetic aspects that lend themselves to beautifully crafted connections.

These industries work together in timber frame construction and joints. They are essential to ensure the joinery is durable, robust and attractive enough to enhance the timber frame structures.

Types of Timber Frame Joints

There are various common timber frame joints, each with its benefits and applications. The joint choice will depend on aesthetic preferences, the builder’s skills and the project’s structural requirements.

- Mortise-and-tenon joints: Mortises and tenons are classic joints. A tenon projects from one piece of timber, fitting comfortably into the mortise on another. It is like fitting puzzle pieces together with a connection that can support heavy loads.

- Tongue-and-fork joints: Tongue-and-fork joints have a protrusion, or tongue, that fits into a corresponding groove in another piece of timber. This construction is beneficial in aligning timbers during assembly and adds more strength to joints.

- Biscuit joints: Biscuit or plate joints feature matching slots in the ends of two pieces of timber that join securely when you insert a small, oval-shaped biscuit coated in glue. The biscuit will swell to create a stronger bond between these two pieces.

- Basic butt joints: These are simple joints where two timbers lay end-to-end, fastening together with bolts, nails or screws. It is a quick and easy process that works well for less demanding applications.

- Dovetail joints: These joints look like a dove’s tail. They have interlocking wedge-shaped projections that fit into matching slots on another timber. Dovetail joints are beneficial in heavy-duty applications like timber frame constructions because they resist pulling apart.

- Halved joints: Also known as lap joints, halved joints have half the thickness of each timber cut off, allowing them to intersect and overlap into a flush surface. They are straightforward to make and work well in light to medium-duty applications.

- Scarf joint: Scarf or splice joints link two end-to-end pieces of timber together with alternating notches at the ends of each piece, often secured with wooden pegs. This technique limits twisting, features intricate design details and is robust enough to support a sturdy structure.

- Splines: A spline passes through the center of a bean’s mortise hole into an open mortise on a supporting beam. Pegs secure this joint.

- Knee braces: These angled supports reinforce joints between horizontal beams and vertical posts. They distribute weight to add stability and prevent lateral movement of the timber frame.

- Trusses: Trusses are triangular-shaped frameworks that support a building’s roof and add details to the building’s architectural style.

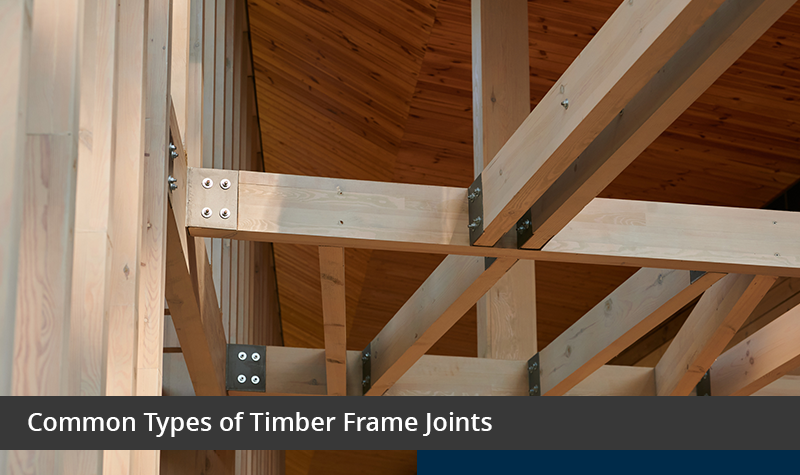

Steel Connections in Timber Construction

Steel connections or combination joints are vital in timber construction. They reinforce connections, creating more robust and reliable joints between components like beams, columns and timber-frame post bases while adding a rugged sense of aesthetic value to your structure. A steel-to-timber connection can bring an industrial factory atmosphere to a traditional rustic timber frame. You can paint or galvanize these plates to suit most interior design specifications and requirements.

These steel connector plates combine with traditional frame joints to support heavy wood spanning great distances. They connect to the timber with bolts, sometimes with a shear placed between to increase the connection’s structural capacity. You can overcome common joint challenges like structural instability and susceptibility to decay by leveraging the benefits of steel connections in timber frame construction. Here are additional ways these connectors can help you mitigate potential problems.

- Increased durability: Steel is excellent at resisting corrosion and decay. This characteristic allows these add-ons to withstand the effects of moisture and other environmental factors, especially in beam-to-column connections.

- Better stability: Steel connections add rigidity to minimize timber frame movement and settling within the frame. This stability helps the frame maintain its structural integrity and can mitigate issues like sagging floors or walls.

- Design flexibility: Incorporating steel can allow more design flexibility, as architects and engineers can create more complete and innovative timber frame structures with various angles, shapes and load requirements.

- Simple installation: Prefabricated steel connectors reduce construction time and labor costs with their streamlined installation process. This method ensures accurate assembly, minimizing the risk of errors during construction.

Contact Mid-Atlantic Steel Fabrication for Timber Connector Plates

Timber frame joinery techniques are a cornerstone of construction, with centuries of durability testifying to their success. These time-honored architectural methods began as early as 200 B.C.E. and are still in use today.

Timber frame plates can boost any joint’s critical stability and visual interest. Mid-Atlantic Steel Fabrication understands the importance of balancing strength with aesthetic appeal. We create high-quality plates that distribute loads in timber frame joints, giving you added peace of mind about your construction project’s longevity. Our welders are industry-certified to D1.1 structural standards, using market-leading CNC equipment. Contact us today to learn more about our metal fabrication services. Request a quote or connect with one of our specialists for a customized design by calling (717) 619-8532.