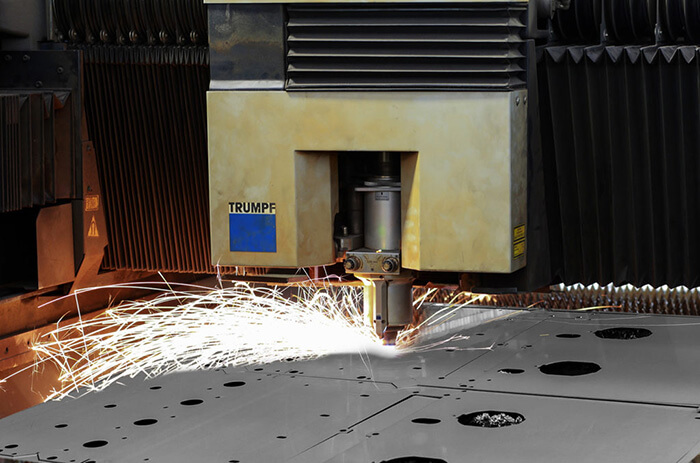

Laser cutting has earned its place as one of the most relied-upon manufacturing processes in modern industry. Known for its precision, repeatability, and flexibility with a wide range of metals, laser cutting has transformed how businesses bring products to life. From aerospace components to food service equipment, this advanced fabrication method plays a critical role in producing dependable, high-quality parts at scale.

What Industries Use Laser Cutting?

The versatility of laser cutting means industries like electronics, construction, and agriculture all benefit from this process. Medical equipment manufacturers also rely on laser cutting for devices that support lifesaving procedures.

For the automotive industry, the use of laser cutting opens up myriad possibilities. When used at various stages, laser cutting will ensure the end product is safe and reliable for consumers. Laser cutting can make intricate cuts and deliver extremely precise finishes with smooth edges, so it reduces material waste and delivers a better finished product. Automobiles aren’t designed like they used to be, so the parts and components are much smaller and more intricate. This makes laser cutting the perfect solution for this industry.

The aerospace industry relies on laser cutting machine use to fabricate pieces like precision parts, gaskets, solar cells, nozzles, and circuit boards. Because of the large-scale nature of the aerospace industry, the cost-cutting attributes of laser cutting have been invaluable. The industry is now able to manufacture commercial aircraft and space exploration projects much more efficiently.

Thanks to the ability to work with multiple materials in a variety of ways, laser cutting is a vital service for many industries and products. Just a few that rely on laser cutting services include:

- Agriculture

- Electronics

- Engineering

- Construction

- HVAC

- Point-of-Purchase Display

- Food & Restaurant Equipment

What Are the Benefits of Laser Cutting?

Laser cutting offers distinct advantages for fabricators and manufacturers:

- Clean, smooth edges with no need for secondary finishing

- High repeat accuracy from piece to piece

- No tool wear, reducing maintenance and production costs

- Flexible contours for unique designs and intricate patterns

This precision and dependability are why so many products that use laser cutting can be found across different sectors.

How Businesses Use Laser Cutting

In construction and engineering, laser cutting enables quick turnaround on complex parts and brackets. For agriculture, it helps create durable components for field equipment. In point-of-purchase displays and commercial food equipment, laser cutting ensures a sleek, functional finish that enhances form and utility.

At Mid-Atlantic Steel Fabrication, we support builders and manufacturers with the technology and expertise to turn custom designs into reality. Our laser cutting machines can handle various grades and thicknesses of steel with speed and precision, which is ideal for everything from structural support parts to fine-detail decorative elements.

What sets us apart is our commitment to delivering more than just laser cutting. We are a one-stop shop for forming, welding, and coating. Every client is matched with a dedicated Project Manager who ensures your specifications are met and your timeline stays on track. For added convenience, we also offer delivery of completed parts for a small fee.

Superior Craftsmanship Meets State-Of-The-Art Technology

Our D1.1 Structural Certified fabricators combine skill with smart technology to bring your vision to life. While turnaround time depends on project complexity, our standard is six to eight weeks. Whether you’re working on a one-off prototype or a large production run, our team is ready to help.

Laser cutting services have allowed the team at Mid-Atlantic Steel Fabrication to consistently produce high-quality, close-tolerance parts and assemblies for various industries. Request your quote and find out why Mid-Atlantic Steel Fabrication will be the right choice as your laser cutting company!