There are likely many metal production suppliers in your area to choose from — so many that you might feel overwhelmed by your options. To help, here are four key things to look for that often separate a good weld shop from a bad one.

- Accurate Designs & Drawings

You might have only a general idea of what your end product should look, or function, like, and that’s okay. A good metal production shop will be able to work with you to produce an accurate design of what the end product should be. Their designer will include detailed instructions and notes so that someone who wasn’t involved in the design process can manufacture your metal product correctly and efficiently without needing additional clarification. This helps to avoid additional project costs caused by production delays and added materials.

- Automation

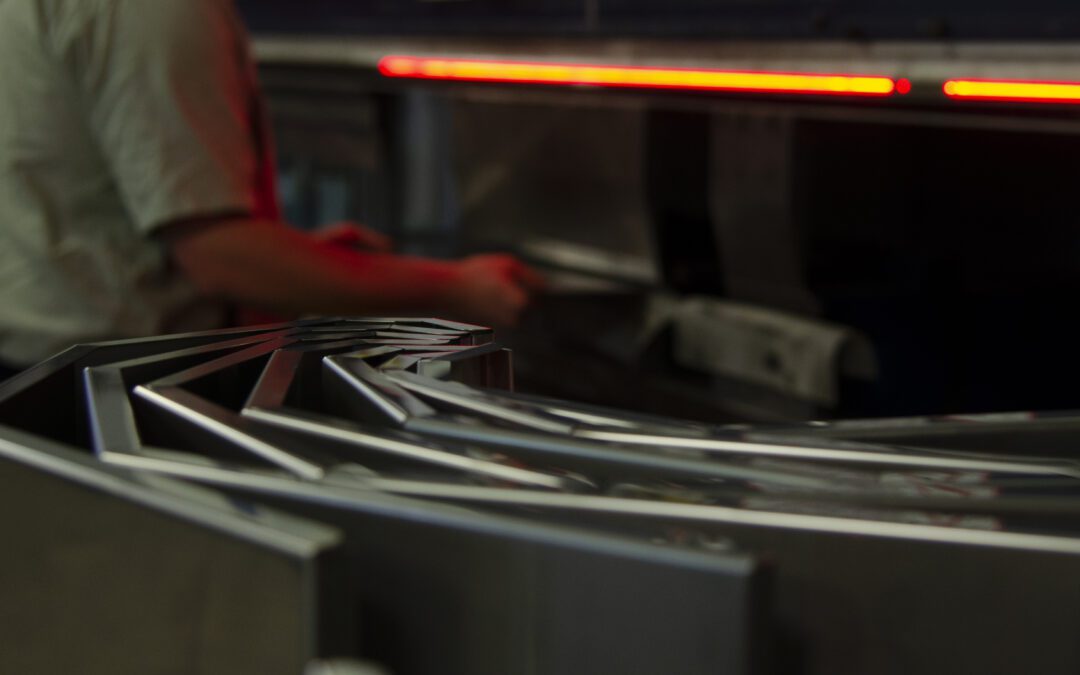

Make sure the metal production company you work with has the right equipment to produce the exact same quality product every time. The speed and accuracy of an automated machine are far superior to any other method of fabricating metal components and parts. Programmable, automated machinery achieves unparalleled consistency of each production piece in a timely manner without jeopardizing the quality of your metal components.

- Quality Control & Inspections

Sometimes, even with accurate drawings and automated machines calibrated just right, there can still be surprises. Look for a metal fabrication shop that routinely inspects machines and individual fabricated pieces — not only for possible defects but also to ensure that the parts are made to the design specifications and work as they should. When a good metal production shop finds a defect or incorrect piece, they’ll work hard to make the appropriate changes and get your finished pieces to you on time.

- Proper Packaging & Shipping

The goal of the metal production process is to get what you need when you need it. Receiving damaged parts can result in project delays and additional costs, so make sure your fabricator packages and ships items properly and efficiently. The shipping process can be bumpy, so adequate padding and protection are very important when packaging your finished production pieces.

A Metal Production Supplier You Can Rely On

At Mid-Atlantic Steel Fabrication, we take great pride in fabricating metal production pieces for our customers. We understand the unique needs of those who hire us, so we’ve outfitted our fabrication shop with state-of-the-art technology and equipment to create whatever is required. Our expert team takes steel fabrication to the next level and stands by everything that leaves our shop. For more information or to start a project, contact us today!