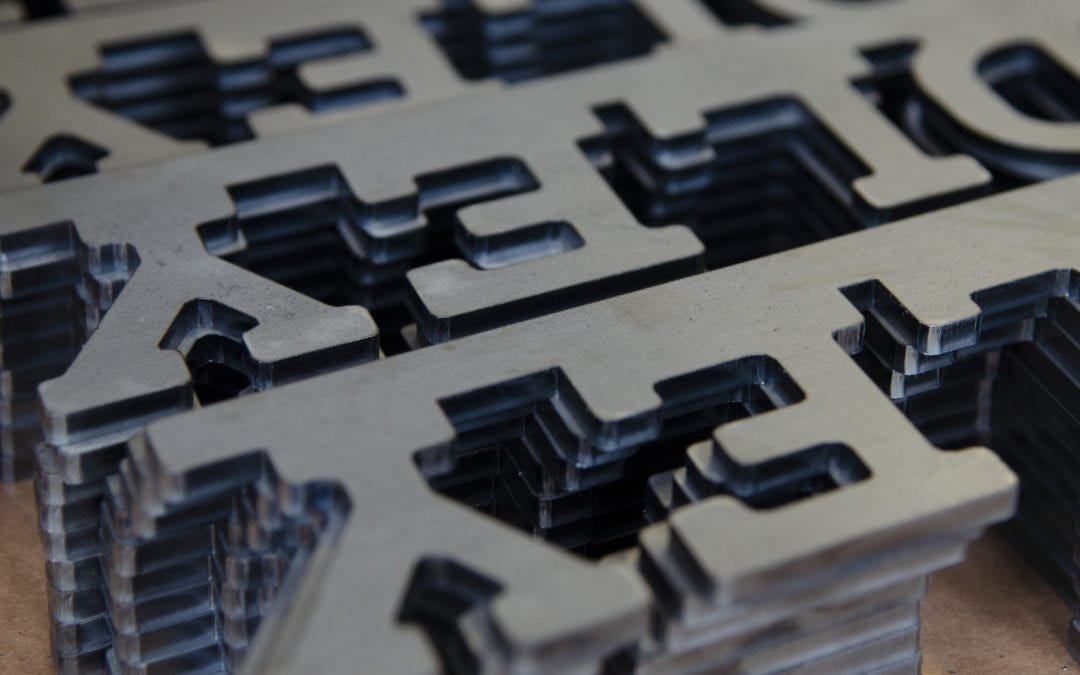

Metal fabrication is a process that involves bending and metal cutting to form a specific structure or product that is then assembled by welding or riveting or fasteners. Metal fabrication often requires multiple processes that aren’t limited to just the bending and metal cutting, and not all of the custom metal fabricators out there have the same capabilities. A custom metal fabricator should have not only the best equipment, but also the design abilities, delivery capabilities, and the capacity to handle projects of any size.

Whether the need is one piece or 1,000 pieces, the Mid-Atlantic Steel Fabrication team can handle the job. We work to continually improve our methods to ensure quality precision metal cutting services suitable for both large and small production runs. Typical projects include any type of sheet metal component, metal stairs, and commercial or residential railings. By using the industry’s best software and equipment, our highly skilled and certified team can design, produce, and finish a custom steel fab part for your unique industrial or manufacturing application.

Not all steel fabrication companies are created equal, so do your research when choosing a steel fabrication company. We have spent years developing our core competencies to deliver quality work every time.

Here are four reasons why you should choose Mid-Atlantic Steel Fabrication as your next custom metal fabricator.

- We are committed to using best-in-class TRUMPF laser cutting service and metal forming equipment. This allows us to consistently produce high-quality parts/assemblies and hold extremely close tolerances.

- From prototyping to large production runs, we can make it happen.

- We offer MIF, TIG, and stick welding. Our entire team of welders holding American Welding Society certification.

- If complete assembly is required, we also offer secondary processes like hardware insertion and tapping and countersinking, along with a wide variety of finishes.